More about REMONDIS

Search

REMONDIS Aqua Company locations

The whole picture – with just a single click. Find out here where our branches are located, what services they offer and how to contact them.

Le sedi del Gruppo REMONDIS

Scopri il mondo di REMONDIS con le sue circa 900 filiali e aziende associate in oltre 30 paesi in Europa, Africa, Asia e Australia.

Sustainable circular water management with REMONDIS Aqua India

REMONDIS Aqua India, a subsidiary of REMONDIS Aqua, is your reliable expert for all aspects of industrial water and wastewater treatment, recycling and ZLD solutions. For more than 15 years, we have been providing customised water management solutions and services to various industries including specialty chemicals, automotive, electro-plating, dairy, metals & mining, food & beverage, fragrance and other sectors.

With our Indo-German collaboration, we support our customers by providing comprehensive solutions. By the virtue of our varied experience, we understand sector-based requirements for industrial water management and the associated challenges. Thus, we offer customized solutions, which are also reflected in our flexible contract models. Our objective in dealing with the most valuable resource, ‘water’, is clear – providing the best for our customers and partners, ecologically and economically. Many domestic and international companies already benefit from our know-how and expertise.

Part of a strong group with wide-ranging network and know-how

Strong alone, unbeatable together. As part of the REMONDIS Group, we benefit from the expertise of one of the world's largest service providers for recycling, services and water. In doing so, we can draw on the Group's wideranging network of plants and know-how. This way, each of our services is also a contribution to the protection of resources.

Our end-to-end services.

Always adapted to your specific requirements

Our services cover all aspects of industrial water and wastewater treatment – from conceptualisation to the commissioning of your plant. We can also take care of the financing part on BOOT model thereby ensuring a long-term partnership. Wherever possible, we also recover valuable resources from your wastewater and thus make an important contribution to the value creation of your company and circular economy.

Concept, design and planning

Inventory and supplies

Trained personnel

Construction work

Financing

Waste management

Lab and analytics

Service and maintenance work

Assistance for environmental compliances

Documentation and reporting systems

ZLD and other innovative technologies as a key component for sustainable water management

We at REMONDIS Aqua integrate innovative technologies into our solutions and provide them as reliable services to our customers. Our ongoing commitment involves innovating our solutions to enhance water quality, maximize wastewater recycling and recover natural resources from waste. The integration of innovative technologies and solutions enables our customers to improve product quality, minimize their water footprint, reduce operational costs and comply with all environmental regulations. With our rich years of experience and know-how, we can support you from conceptualisation to commissioning as well as financing of your plant.

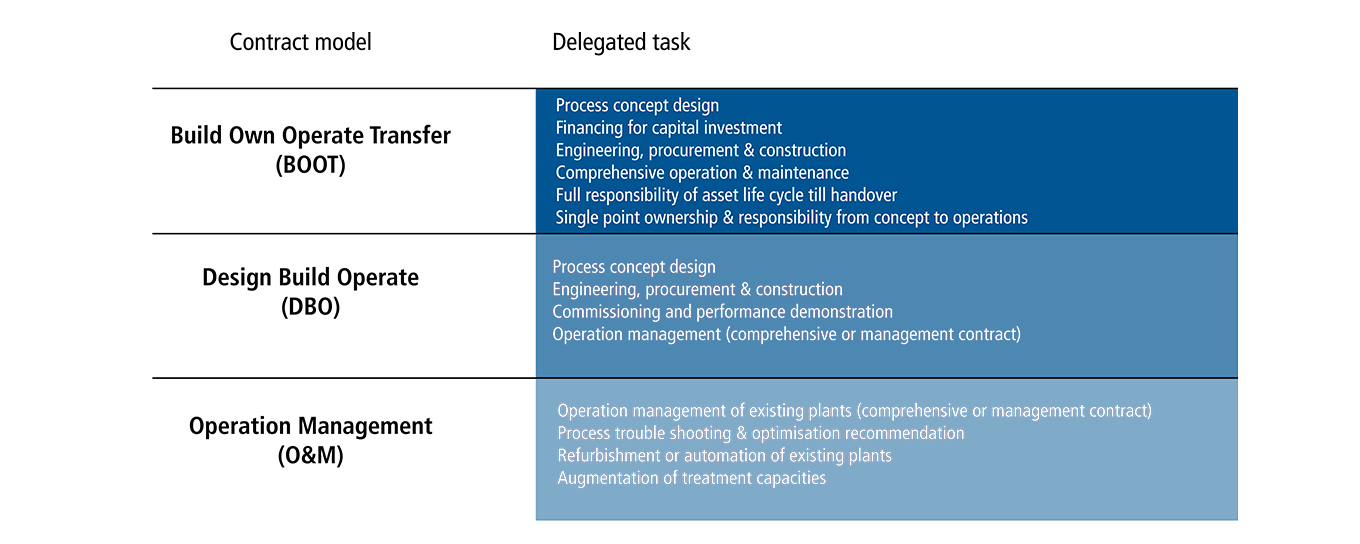

Flexible business models for your individual needs

We offer flexible cooperation business models to meet your individual needs. Our services range from conceptualisation to operations.

Are you interested in our range of services? Please feel free to contact us or follow us on LinkedIn!

Benefits of our cooperation at a glance

With REMONDIS Aqua India, you have a strong, long-term partner at your side whose experience and know-how you can rely on at all times, bringing you various benefits. Convince yourself:

End-to-end services under one roof

Our services cater to the entire water cycle from raw water purification to effluent treatment, recycling and Zero Liquid Discharge, making it possible for our customers to offload the entire water management to a single-point responsibility model over the course of long-term contracts.

Brand value

With an admirable growth story spanning over 80 years and a committed vision to work for a sustainable future, today REMONDIS is one of the most reliable industrial partners for providing services and customised solutions within the recycling and water sectors.

Customized design

We design with well-established and proven treatment technologies based on our extensive international operational experiences covering various industries and complex effluents. Operational experiences are reflected in our plant designs, making them sensible rather than just innovative.

Ideal equipment and technology

Our flexibility with technology and equipment selection gives us the freedom to provide our customers with what is required rather than pushing for in-house products.

Transferral of risks

With REMONDIS Aqua India, you outsource your risks. Regardless of whether they are a planning risk, operational risk or cost risk.

Reliable performance

Reliable performance is guaranteed by combining the aforementioned factors. Additionally, we offer complete capital expenditure (CAPEX financing through long-term BOOT or DBO contracts, which provides extended insurance for the asset's lifespan and performance to our customers.

Selected Industrial References

Automotive Industry

Ideal wastewater management for the automotive industry

The Volkswagen plant in Pune is one of the largest investment projects by a German company in India.

The project

REMONDIS Aqua is responsible for the wastewater treatment at Volkswagen's production facilities in Pune. Within the framework of a BOOT model, REMONDIS Aqua built, operated and maintained the facilities for a period of 5 years.

The procedure

Two of the plants each of 500 cubic metres of the highly contaminated wastewater per day from the paint shop, sewage and other production using a biological wastewater treatment process with subsequent membrane bio-reactor (MBR). A third plant cleans another 500 cubic metres, also biologically, in a sequential batch reactor (SBR). The treated wastewater can finally be used for irrigation purposes. The sewage sludge produced in the purification process is dewatered, dried and used as manure.

REMONDIS' scope

- Safe wastewater treatment through modern technologies

- Compliance with environmental standards and water protection

- Planning, construction and operation from a single provider

- Resource conservation through recycled water

Secure treatment of effluents in the automotive industry

Mahindra and Mahindra Ltd., the flagship company of the Mahindra Group, is a leading Indian multinational automotive manufacturer and the world’s largest tractor manufacturer by volume.

The project

REMONDIS Aqua is responsible for designing and building a complex effluent treatment and recycling plant at Mahindra’s Chakan site. As part of the DBO model, REMONDIS Aqua has been contracted to design, install, and commission a new 3,300 m³/day effluent treatment plant (ETP). This includes electro-mechanical and civil work under Phase-I, with an ambitious eight-month delivery timeline.

The procedure

The existing wastewater treatment plant is designed to treat a combined effluent from industrial and domestic sources at Mahindra’s automotive manufacturing facility. The new process will segregate sewage from industrial effluents, with a new ETP and recycling plant designed to handle the additional effluent generated by the facility's expanded production capacity, which will total 3,300 kiloliters per day (KLD).

REMONDIS' scope

- Process concept design

- Engineering, procurement and construction

- Safe wastewater treatment using modern technologies

- Comprehensive planning, construction and operation services from a single provider

- Resource conservation through water recycling

- Compliance with environmental standards and water protection

(Specialty) Chemical Industry

600 KLD Zero Liquid Discharge wastewater treatment in the speciality chemicals industry

Evonik is a global leader in speciality chemicals with a presence in over 100 countries and over 33,000 employees. Besides its headquarters in Mumbai, Evonik has two manufacturing facilities and several research, development and innovation laboratories in India, serving customers in India, Bangladesh, Nepal and Sri Lanka.

The project

REMONDIS Aqua is the selected service provider and responsible for the wastewater treatment facilities and Zero Liquid Discharge Plant at Evonik’s production site in Dombivli, Maharashtra. As part of BOOT model, REMONDIS Aqua has financed the entire capital cost and the plant is in successful operation since 2022. REMONDIS Aqua is responsible for its comprehensive operation and maintenance for a period of 10 years.

The procedure

The wastewater with high dissolved solids will first be pretreated chemically before passing through various stages of filtration. The concentrated brine is then fed into multi-effect evaporators, which recover the remaining water and ensure that not a drop of wastewater is released into the environment. High-purity sodium sulphate is also recovered as an by-product through special dryers and automatically bagged for reuse in the industry with commercial value.

REMONDIS' scope

- Process concept design

- Financing for capital investment

- Engineering, procurement and construction

- Comprehensive operation and maintenance

- Full responsibility of asset life cycle until handover

- Single-point ownership and responsibility from concept to operations

Safe effluent treatment for the chemical industry

LANXESS is a leading speciality chemicals group and has many production sites worldwide. At its site in Jhagadia, Gujarat, LANXESS has production facilities for its four business units liquid purification technologies, material protection products, rhein chemie and high-performance materials.

The project

REMONDIS Aqua is responsible for industrial effluent treatment and a sewage treatment plant at the Jhagadia site. Within the framework of an Operation & Maintenance contract, REMONDIS Aqua operated and maintained the wastewater treatment facilities for a period of 10 years.

The procedure

Through the industrial effluent treatment plant, various effluent streams from the LANXESS production sites are treated in a three-stage extended activated sludge process. Approximately 2,500 cubic metres of effluent is treated in this way every day. In the sewage treatment plant, another 100 cubic metres of sewage is treated daily through a moving bed bioreactor (MBBR) process. The treated sewage is then used for irrigation purposes.

REMONDIS' scope

- Safe wastewater treatment through modern technologies

- Compliance with environmental standards and water protection

- Planning, construction and operation from a single provider

Metal & Plating Industry

Secure treatment of electroplating effluents

Polyplastics Industries is a leading OEM for automobile components with a history spanning over 50 years. The company specialises primarily in spare parts for the automotive industry and offers a comprehensive range of products. The main production processes are injection moulding, painting, tool manufacture and electroplating.

The project

REMONDIS Aqua is responsible for treating the effluents from the electroplating process and recycling the water back to the production process. The wastewater contains heavy metals such as chromium, zinc and nickel, among others. According to a DBO model, REMONDIS Aqua designed, built, and is operating the industrial effluent Zero Liquid Discharge plant.

The procedure

Through the industrial effluent treatment plant, various effluent streams from the Polyplastics production sites are treated by chemical precipitation followed recycling via membranes and multi-effect operation.

REMONDIS' scope

- Safe wastewater treatment through modern technologies

- Compliance with environmental standards and water protection

- Planning, construction and operation from a single provider

- Resource conservation through recycled water

Recycling & Zero Liquid Discharge (ZLD) for the metal and mining industry

Kutch Copper Ltd., a subsidiary of the Adani Group, operates the world’s largest single-location custom smelter located in Mundra, Gujarat. The Phase-I copper refinery is set to produce 0.5 million tons annually (MTA) of refined copper, with plans to scale the plant to a full capacity of 1 MTA.

The project

REMONDIS Aqua is responsible for treating the complex effluent from the copper refining process and recycling it back into production, creating a closed-loop system. As part of the DBO (Design, Build, Operate) model, REMONDIS Aqua has been contracted to design and construct the plant on a fast-track basis.

The procedure

The effluent treatment plant (ETP) is designed to treat effluent containing concentrated dissolved metal impurities generated during the pyrometallurgical, copper recovery, electrowinning (EMEW), and cast wheel process stages at the copper refinery. The treatment methodology incorporates innovative physico-chemical processes developed by REMONDIS, along with state-of-the-art, energy-efficient ZLD technologies from Germany. The treated water will be of high purity, suitable for reuse in production processes, thus enabling a closed-loop water cycle.

REMONDIS' scope

- Concept design

- Engineering, procurement and construction

- Commissioning and performance demonstration

- Operations to establish a closed-loop water balance

Dairy Industry

Ideal wastewater management for the dairy industry

Milky Mist Dairy, renowned for its high-quality dairy products and sustainable practices, continues to set an industry benchmark with its cutting-edge production facility and expansion plans.

The project

REMONDIS Aqua has been entrusted with designing and building a sludge digester and biogas handling system alongside a complex effluent treatment and recycling plant at its Perundurai, Tamil Nadu site. As part of the DBO model, REMONDIS Aqua is designing and constructing a Zero Liquid Discharge (ZLD) effluent treatment and recycling plant, scheduled for completion within seven months.

The procedure

REMONDIS will design and build an energy-efficient ZLD plant incorporating a sludge digester, membrane bioreactor, multi-stage reverse osmosis, nanofiltration, evaporation, salt separation, and drying. The treated water will be pathogen-free and of high purity, ready for reuse in production processes.

REMONDIS' scope

- Process concept design

- Engineering, procurement and construction

- Safe wastewater treatment using modern technologies

- Comprehensive planning, construction and operation services from a single provider

- Resource conservation through water recycling

Join us in shaping the future of water management in India! Just send your application

to Rahul Nerlekar